TV NEWS PROJECTS

After working for KPIX News for 5 years I was lured away by KRON with the inviting proposal that I would be allowed to work at home and equip three new ENG trucks. The first two (seen here) would be bare-bones. With whatever funds remained I could equip the third truck as a super truck and assigned to me. Because of differing union contracts, I would also be able to act as the engineer and also the cameraman. I would switch once a week with my partner. It was too good an offer to pass up – at least it seemed that way at the time.

My super truck is on the next slide…

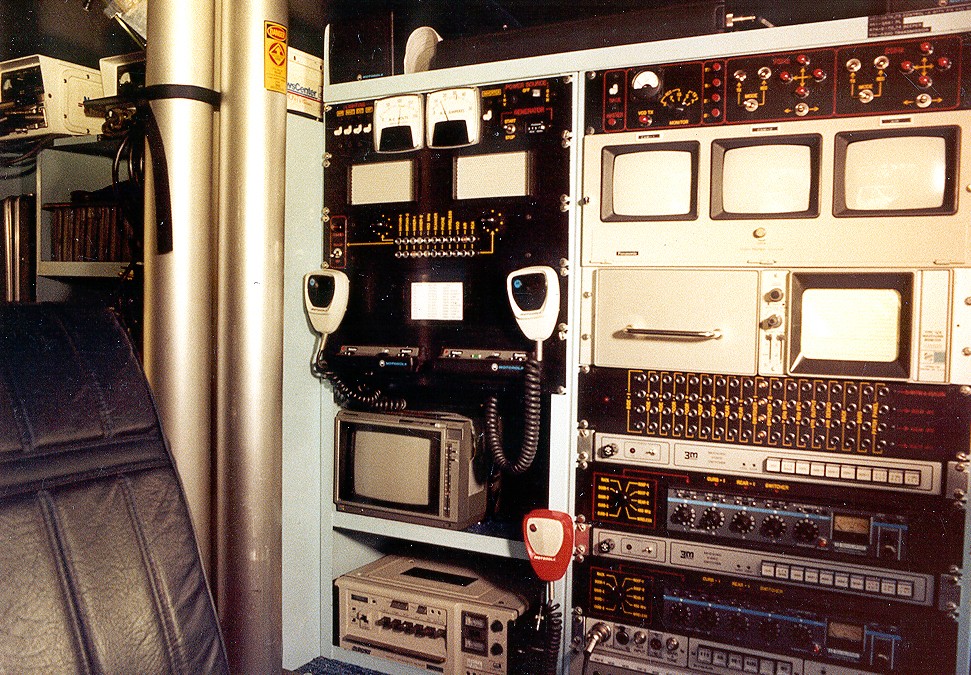

KRON VAN-9

I equipped seven ENG trucks in the course of my 13 years in TV News. This one had two pneumatic masts and was capable of originating multi-camera live shots and was frequency agile on 2 GHz, 7 GHz, and 13 GHz. It also had extensive communications and monitoring capabilities and could act as a relay for other ENG trucks. It was my baby.

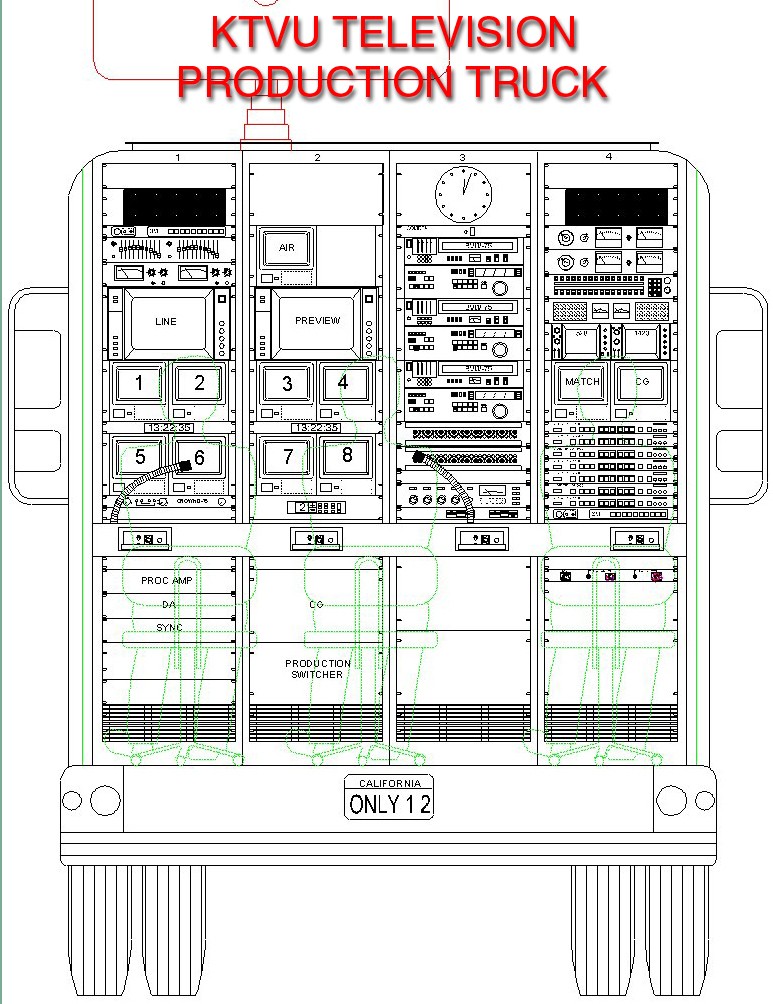

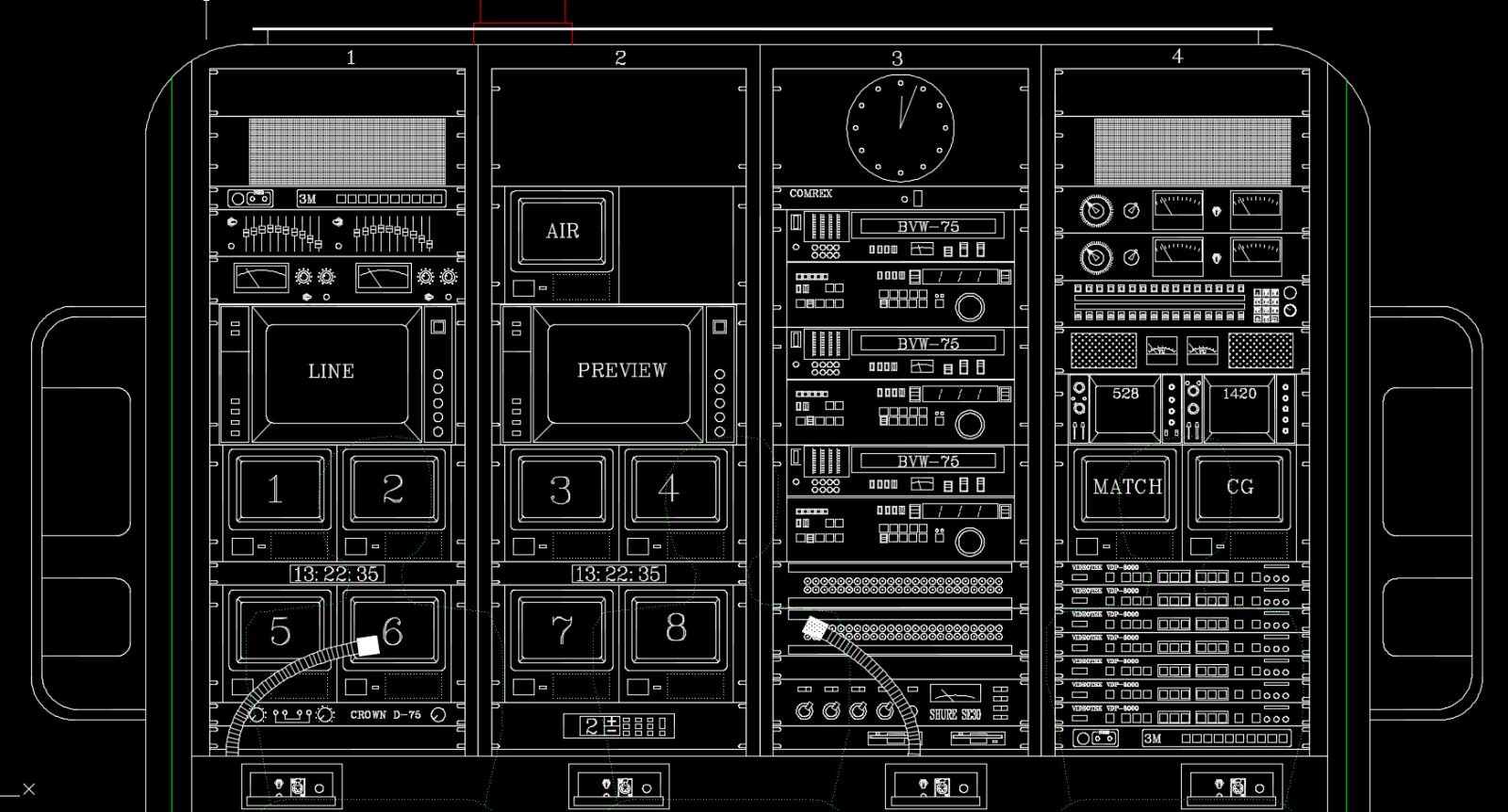

KTVU TV

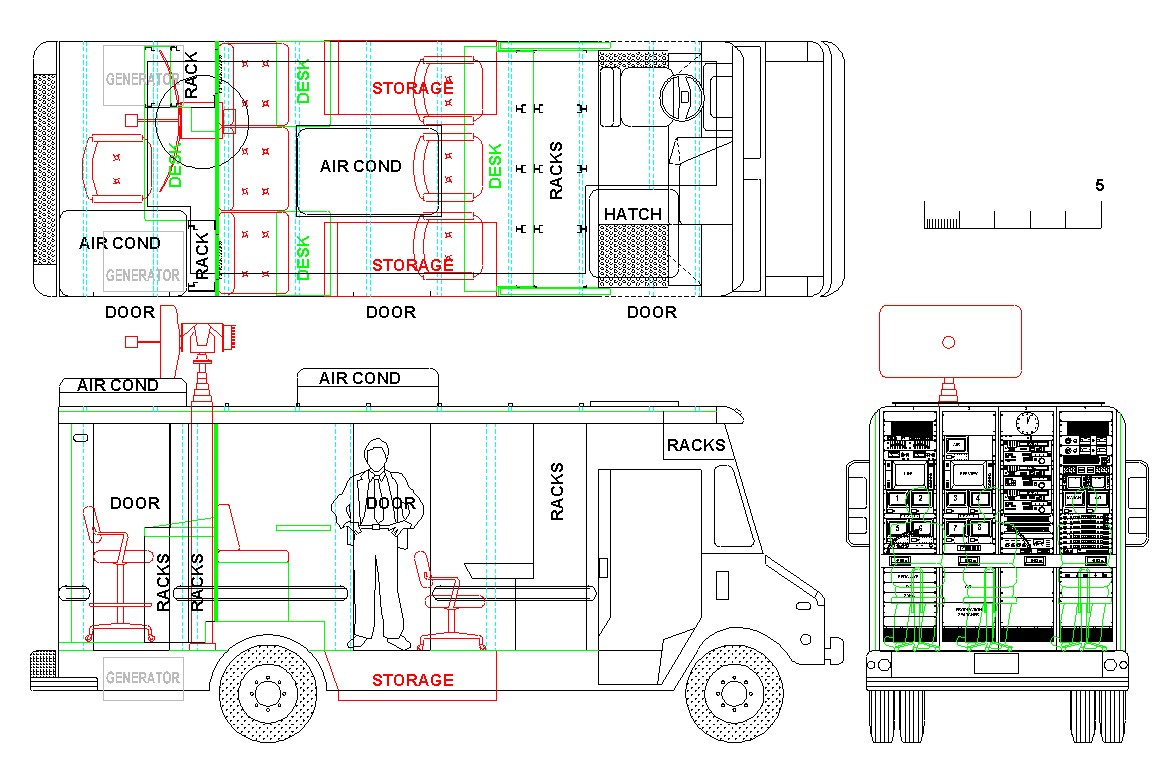

I combined ENG News Gathering with Engineering design and construction. This is my design for a Production Truck for KTVU…

This truck was designed to originate multi-camera remote broadcasts. In the past the engineering department would have come up with a design and then built it. Then the production crew would try to use it and return

with a large list of complaints. By going the design in AutoCAD it was possible to get the production crew’s feedback before construction began and make the changes on the computer. All the various pieces of equipment were virtual blocks that could be easily moved. I used a 1.75-inch by 1 inch aspect ratio setting for my snap setting, so pieces could be moved in one rack-unit increments…

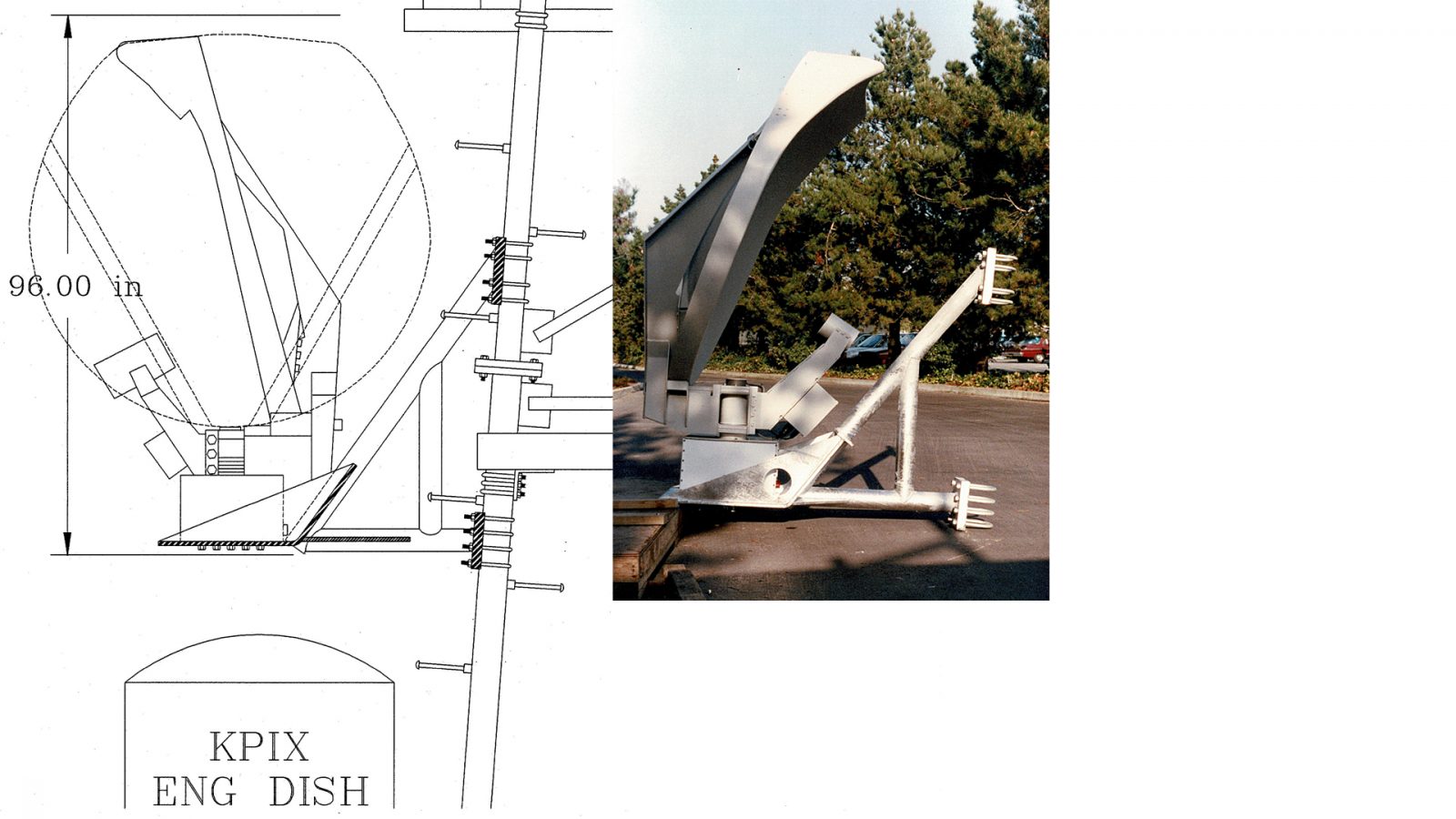

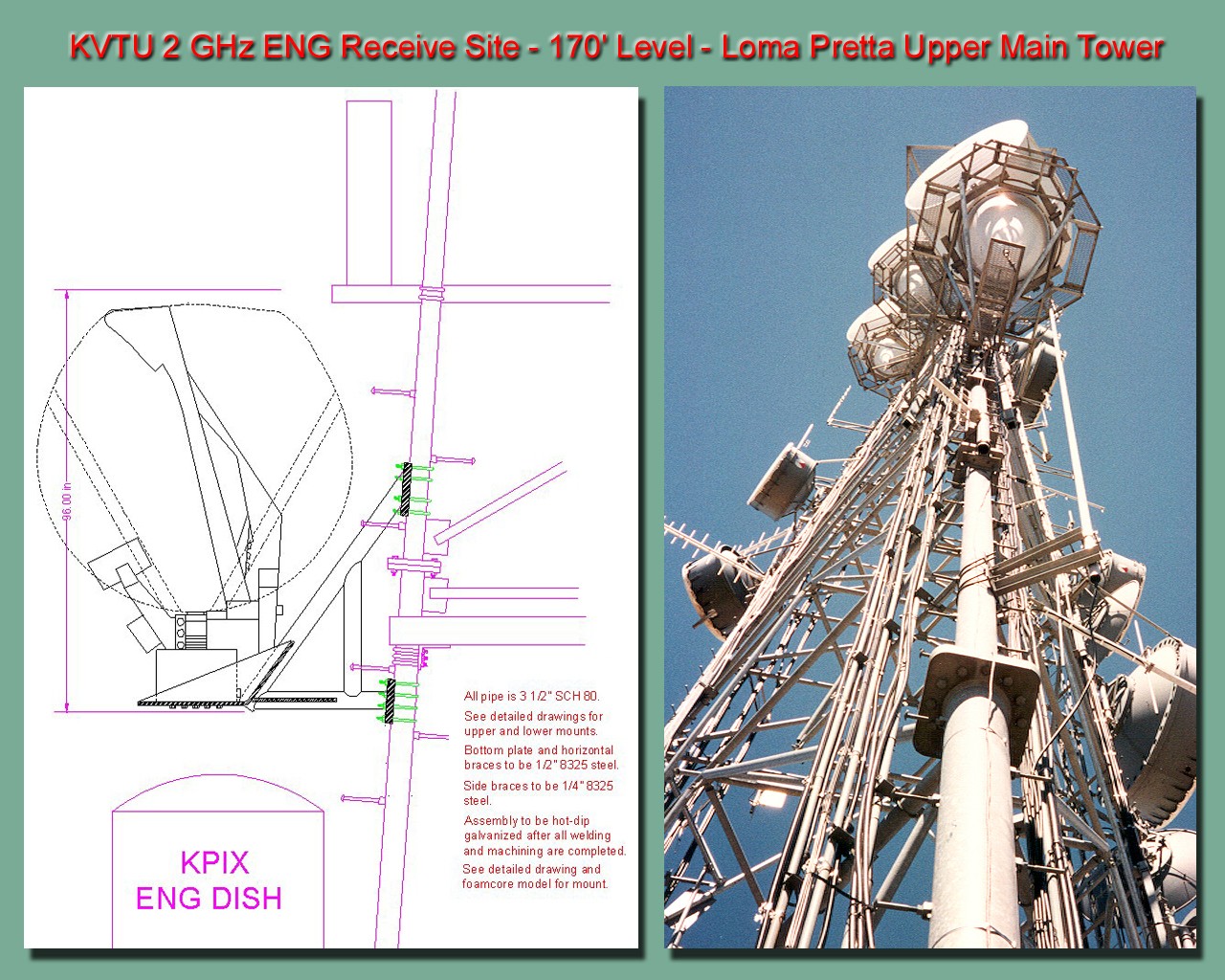

KTVU TV REMOTE 2 GHz RECEIVE SITE

I veneered for this project. It was way outside of my job description. It survived the Loma Prieta Earthquake with out a single hiccup. Rear on to enjoy my reward for a job well done!

My engineering challenge here was to shoehorn this 900-pound, 8-foot tall dish into a small space on a very crowded tower. I spent many hours at the 170-foot level carefully measuring every item on that tower leg. The dish mount had to straddle all of the existing hardware as nothing could be moved. Once the dish mount was fabricated professional riggers did the actual installation. This stuff was very heavy! That dish survived the Loma Prieta Earthquake and has been in operation for 30 years.

This tower was packed to capacity with equipment. Finding a spot on the valley-facing leg, as high as possible, was a challenge! The only spot available was inches above a very delicate fiberglass radome, and directly under another antenna. I had to design a mounting structure that would fit, be extremely strong, and take into account the slope of the leg.

This dish survived the Loma Prieta Earthquake and was in service for at least 30 years, It’s probably still there…

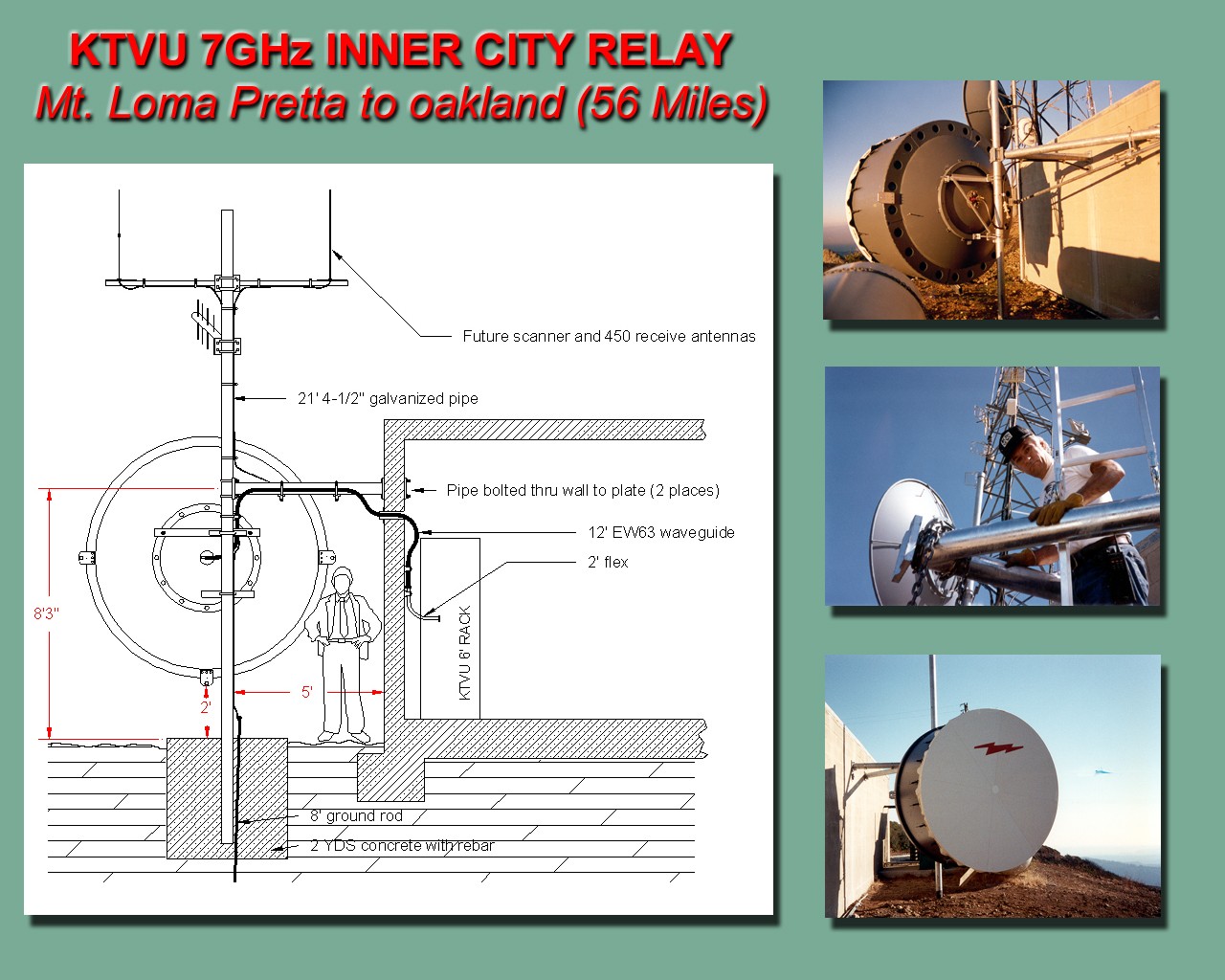

We could not link back to the studio from the receive site since a Monterey TV station was using the 7 GHz band to uplink their programming to Loma and we would cause interference. So the Inner-City 7 GHz transmit site was on the other side of the mountain and linked by fiber. Each site had independent backup power, so no wiring could connect the two sites (huge ground loops!) This installation was put into operation only weeks before the Loma Prieta Earthquake and survived without a problem.

I designed this mount to withstand just about anything. I had no idea the Loma Prieta Earthquake was only weeks away!

Aside from the physical challenge of mounting the dish, the link had to co-exist with all of the 7 GHz systems already in operation. This dish was optimized for minimum side lobes and favored one side which was protecting an existing link..

The PVC conduit carrying the fiber optic, coaxial, and control cabling was buried in a trench and surrounded with sand to protect it. In the event of a power failure, the backup diesel generators at both sites would power each individual site, resulting in huge ground loops. Isolating the sensitive electronics in each site with optical fiber would prevent problems.

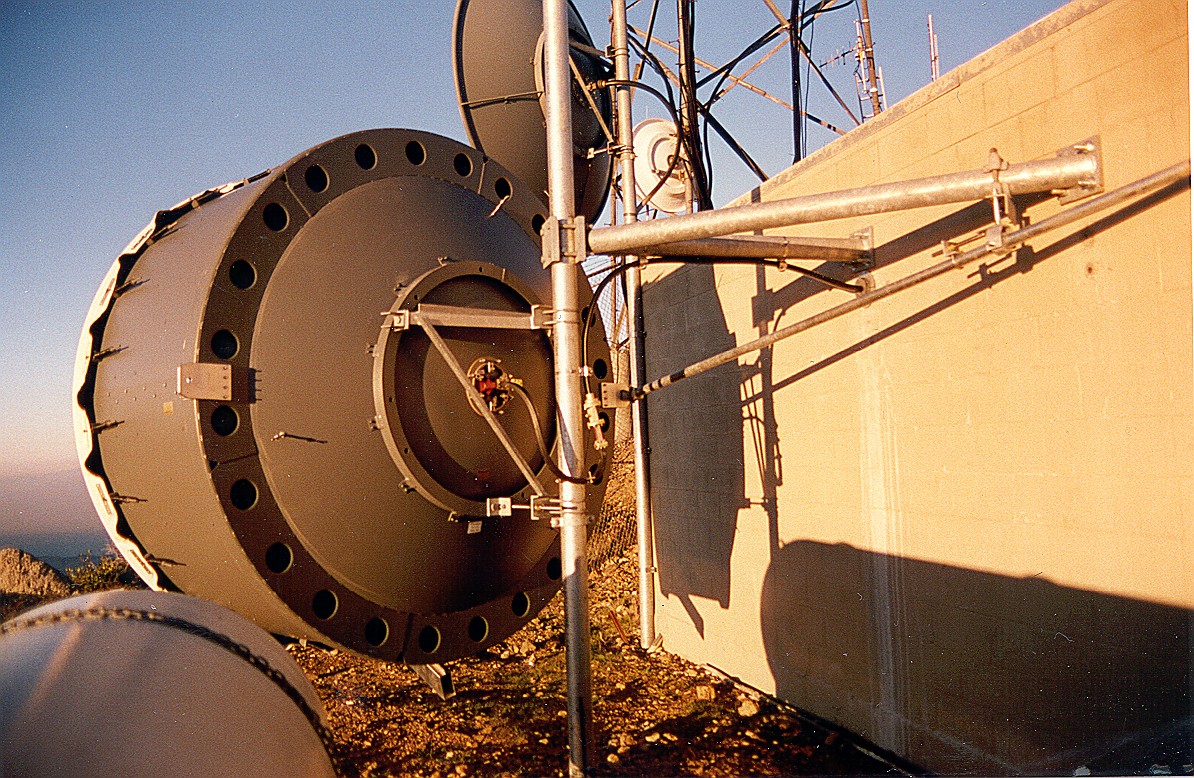

This is the business end of the 8-foot Andrews extreme high efficiency dish. That supporting pipe is anchored in the ground with one cubic yard of concrete, weighing approximately 2,700 pounds, and braced at the top with a triangle consisting of the two arms that but up against the wall, and a 1/2-inch steel plate on the inside that spans across the two legs to form the third leg of the triangle.

The interior sides of the dish as covered with RF absorbent foam to suppress sidelobes, and the feed is designed to favor one side of the pattern, so you can further protect the most venerable existing system.

When I finished the project I was told by the KTVU chief engineer that I had exceeded his mystery budget, and I would not be getting the bonus I had been promised.