LABVIEW

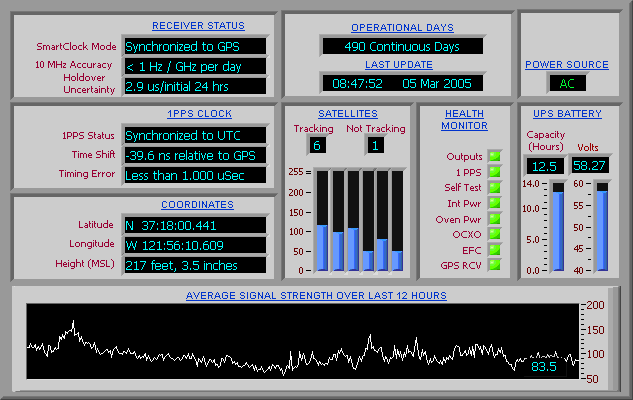

I created this LabVIEW application (a “VI”, or “Virtual Instrument”) in LabVIEW, to monitor my GPS Disciplined Clock.

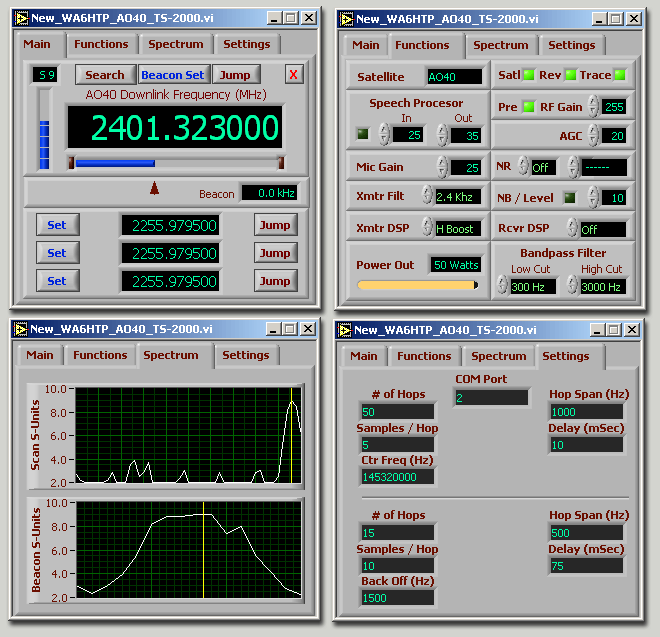

This VI controlled my TS-2000 Transceiver and did the math to show my operating frequency while working the AO-40 Satellite. As you can see, it also did much more, but you get the idea…

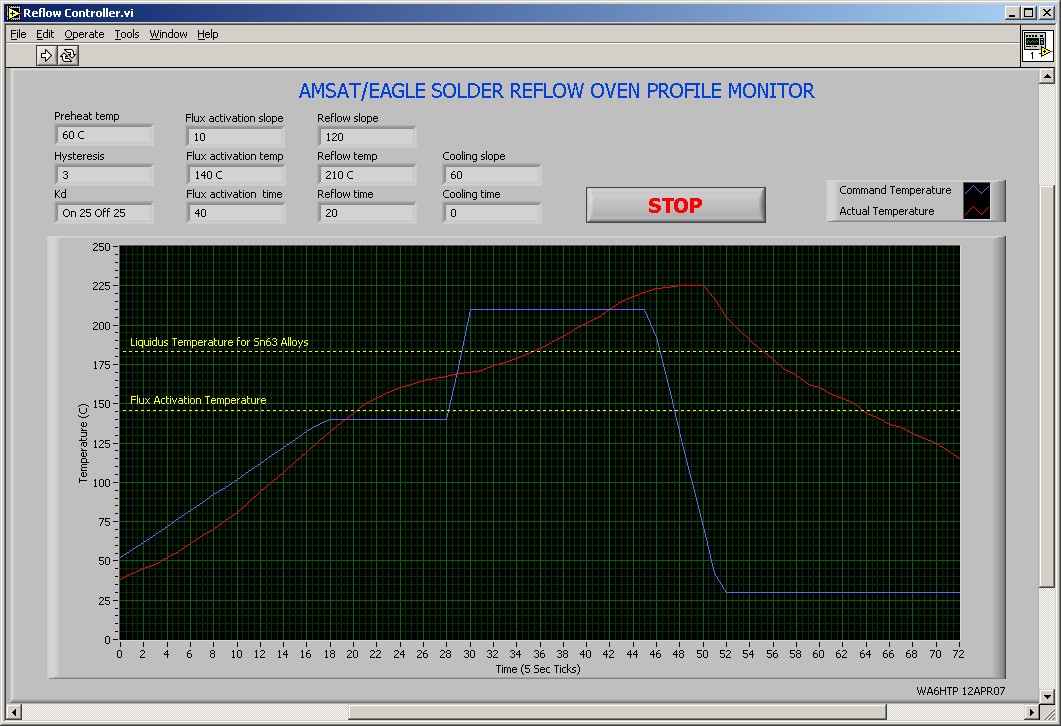

AMSAT/EAGLE SOLDER REFLOW OVEN PROFILE MONITOR – The blue line is the ideal temperature profile. The red line is the actual temperature vs time readings, (The oven is a converted Toaster Oven!

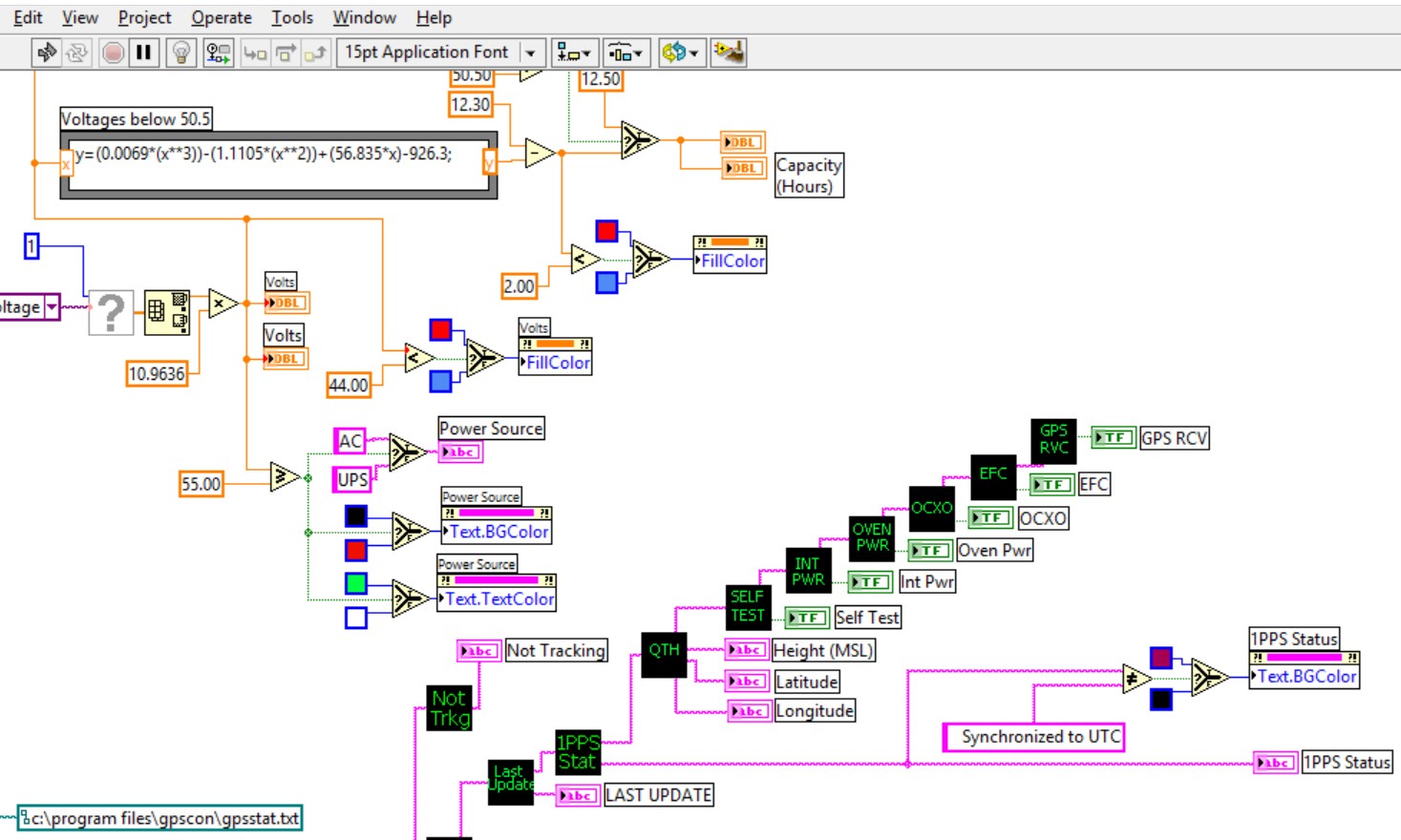

This is a small portion of the GPS Monitor code.. It’s an extremely high-level graphical programming environment. Each of those black icons is a “Sub-VI”. a Sub-VI contains a block of code that has been corralled into a logical block. Sub-VI’s can be nested, so the underlying code can be extremely complex and powerful. Each of the colored icons performs a logical function – and gate, comparator, etc. Some are extremely powerful, such as the math box in the upper left. It contains a 2nd order polynomial equation. The “X” value is being inputted on the left, and the output is feeding other logic on the right.