United Airlines

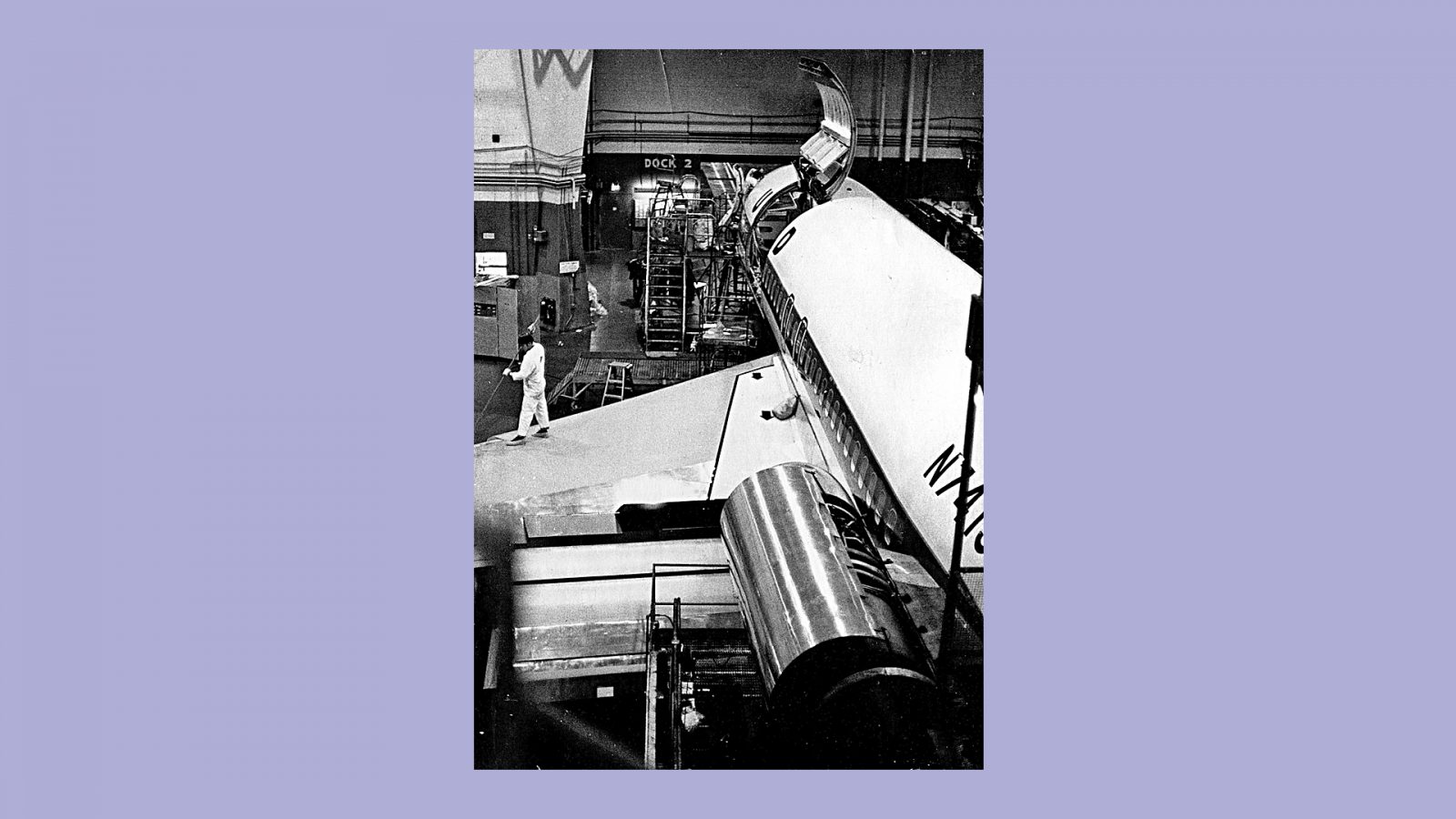

I spent five years working for united Airlines as a radio and electric line maintenance mechanic at SFO. This is the only picture I have to show for five years of graveyard shift!

This is a Boeing 727 quick change aircraft. See that big door toward the nose? During the daytime the plane flew up and down the west coast carrying passengers, but at night, all the seats, galleys, and heads could be removed in 45 minutes, turning this plane into a freighter, It could then continue to earn revenue at night.

All new mechanics started out doing routine maintenance until they were very familiar with that particular aircraft type. One of my first assignments used to be checking every light on the aircraft, and there are many - reading lights, stewardess call lights, fluorescent valence lights, seat belt lights, etc. Then on to the cockpit for red and white overhead lights, shite, and finally, exterior lights - inboard and outboard landing lights, taxi light, runway turnoff lights, navigation and strobe lights... You get the picture.

Once you satisfied the supervisors that you were not a menaces you were assigned more demanding work such as checking the yaw damper which required hydraulics and moved the tail surface. That can be a danger to other mechanics, so you needed to have earned trust. Eventually I was moved to checking avionics, navigation, HF and VHF communications and weather radar.

After a year or two, and learning all the systems on the variety of 727, 737, and DC8's in the fleet, I was moved to non-routine maintenance. That's where you are assigned an aircraft, go out, look at the logbook, find out what problems may exist, and fix them. That was much more challenging, and that's what I did for the rest of my time at United.

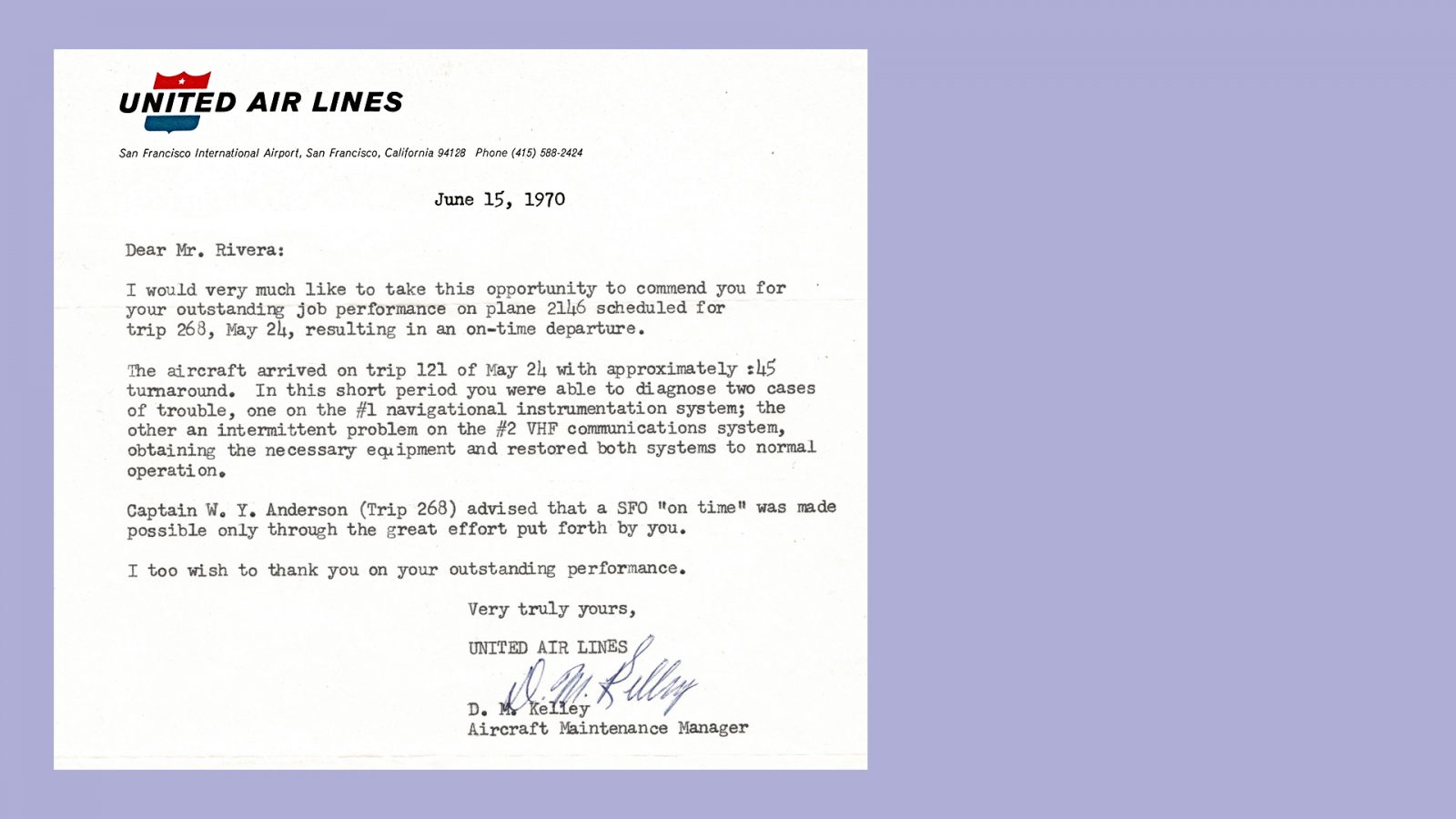

It's been my experience that you don't often receive an AtaBoy from a top manager, so I have hung onto this one for fifty one years. Since this slideshow is decidedly weak on content I might as well post it here...

This particular afternoon I was the only maintenance R&E mechanic at the terminal, so it was my job to meet every incoming aircraft at the gate and see if they were able to depart on time. This one was definitely not, and I had only 45 minutes to troubleshoot their problems and fix them all.

Most aircraft instruments in the days before glass cockpits, were mechanical and had a red flag that would pop out and block the indicator. The flag was red and said "FAIL" or "INOP", for Inoperative. Almost every instrument on the main instrument panel had a FAIL flag sticking out. It was a mess and the flight crew had given their aircraft up for dead...

Fixing the #2 VHF communications system was a no-brainer. I swapped out the #2 VHF transceiver, got a radio check, and signed that one off. The only thing all the other faults had in common was a directional gyro. Swapping that out cleared all those red flags and I went off to work on the next aircraft. Just another day at the office...